In every industrial plant, utility substation, and critical facility… there’s one silent guardian keeping operations safe and steady: The switchgear.

You may not notice it when everything runs smoothly. But when something fails… production stops, safety alarms trigger, and maintenance teams race against time.

That’s why preventive maintenance of switchgear isn’t just good practice—it’s critical.

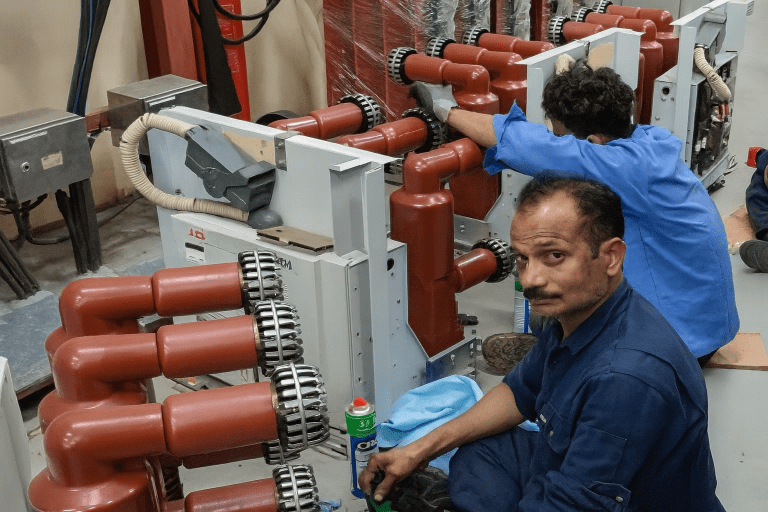

At Petrozone International, we’ve spent years in the field, working shoulder-to-shoulder with maintenance teams across cities like Riyadh, Jeddah, Dammam, and beyond. From dusty desert substations to coastal industrial plants…

We’ve seen what happens when maintenance is done right—and when it’s ignored.

This guide brings all that experience to you.

Whether you’re a maintenance engineer, plant supervisor, or procurement specialist looking for reliable service partners, this guide will help you understand:

✅ What is Switchgear?

✅ Types of Switchgear used in Saudi Arabia

✅ Major Switchgear Manufacturers in the region

✅ How Switchgear works

✅ Critical Switchgear components and their functions

✅ How to perform Preventive Maintenance

✅ Why Petrozone is trusted for Switchgear Maintenance

Quick heads-up… this blog comes with riddles, real stories, and a free guide at the end. Stay with us—it’s more fun (and useful) than you think.

What is Switchgear?

At its core, switchgear is a system of electrical devices designed to control, protect, and isolate electrical equipment. It includes components like disconnect switches, fuses, circuit breakers, and relays, all working together to ensure that electricity flows safely and stops instantly during faults.

In simpler terms:

“When power misbehaves… switchgear steps in like a bodyguard for your electrical system.”

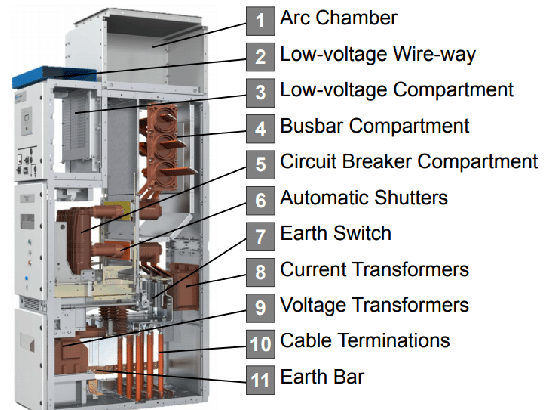

Know Your Switchgear critical components

Before diving into the Blog, it’s essential to understand the key components inside the switchgear you’re dealing with.

Here’s what you’ll typically find inside a switchgear panel:

- Circuit Breakers: Interrupt power flow during faults or overloads.

- Protection Relays: The system’s brain—detects abnormal conditions and sends trip commands.

- Busbars: Distribute current within the panel.

- Current Transformers (CTs) and Voltage Transformers (VTs): Step down high voltage and current levels for safe metering and protection functions.

- Meters and Instruments: Provide real-time system monitoring and performance data.

Now that you’re familiar with the main components, let’s dive into the step-by-step switchgear maintenance process.

Medium Voltage Switchgear Types Commonly Used in Saudi Arabia

In Saudi Arabia’s industrial and utility sectors, medium voltage switchgear plays a key role—especially in 13.8 kV and 33 kV networks.

The most common types include:

- Air Insulated Switchgear (AIS): Widely used in substations and industrial plants.

- Gas Insulated Switchgear (GIS): Preferred for space-constrained areas and offshore platforms.

- Hybrid Switchgear: A compact combination of AIS and GIS.

- Ring Main Units (RMU): Popular for medium voltage distribution in urban and industrial settings.

At Petrozone, our maintenance teams are regularly deployed across Saudi Arabia, working on both AIS and GIS switchgear, handling both routine maintenance and emergency response

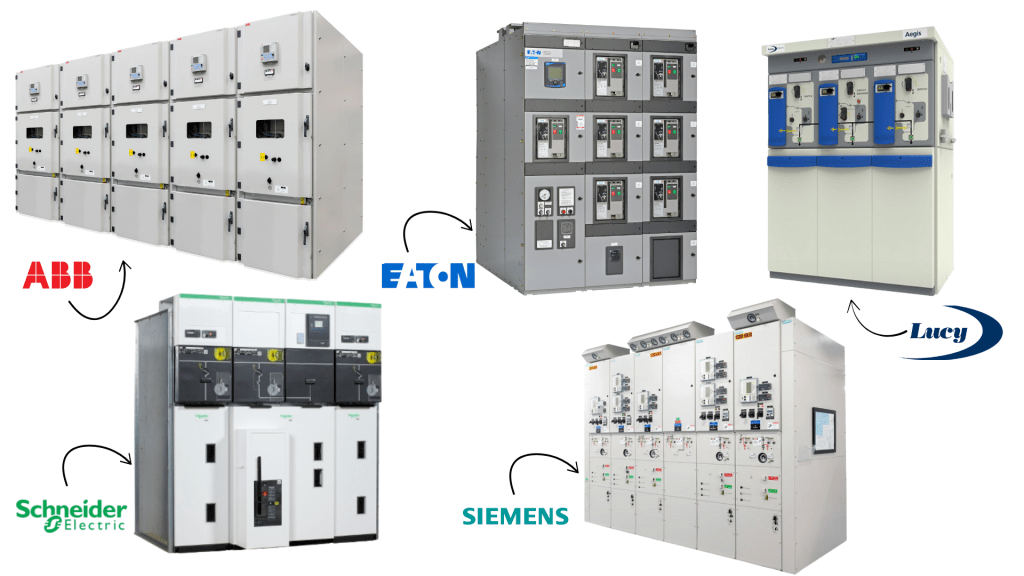

Who Are the Leading Switchgear Manufacturers?

Over the years, industries across the region have trusted major global brands like:

- Siemens: Renowned for the 8DA10 gas-insulated switchgear (GIS) and NXAIR air-insulated switchgear (AIS), both widely deployed in substations and industrial facilities.

- ABB: Offers the UniGear series, including models like UniGear ZS1, known for their modular design and adaptability in various applications.

- Schneider Electric: Provides the SM6 AIS panels and RM6 GIS units, both prevalent in medium voltage distribution networks across the Kingdom.

- Eaton: Features models such as the Power Xpert UX, Power Xpert XGIS, and VCP-W, offering flexible AIS and GIS solutions suitable for demanding environments.

- Lucy Electric: Specializes in Ring Main Units (RMUs) like Aegis Plus, Sabre, and Trident, designed for secondary distribution networks and capable of operating in extreme environmental conditions.

- GE: Known for the Power/Vac metal-clad switchgear, offering robust solutions for both legacy systems and modern installations.

At Petrozone, our engineers have hands-on experience working with all major switchgear brands—whether it’s maintaining a Siemens 8DA10 , an ABB UniGear, or a Schneider SM6 or RM6 panel. No matter what the make or model, we understand the unique build, protection logic, and service requirements of each system, ensuring your switchgear stays reliable, compliant, and always ready for operation.

How Electrical Switchgear Works

The switchgear acts like a control tower for your electrical network. It provides constant monitoring, keeping a close watch on the system load and overall health at all times.

When a problem occurs—like a short circuit or overload—the fault detection function kicks in. The protection relay senses the fault within milliseconds and sends a signal for immediate action.

This leads to quick isolation of the faulty section by the circuit breaker, while ensuring power continuity to the healthy parts of the network. As a result, your lights stay on, your machines keep running, and your team stays safe.

“What watches without blinking, reacts in milliseconds, and keeps your lights on when trouble strikes? Your switchgear, of course!”

What is Switchgear Maintenance?

Dust, heat, moisture, and electrical stress—your switchgear faces all of it, every single day. Over time, these factors quietly weaken insulation, corrode contacts, and slow down moving parts.

Preventive maintenance isn’t about paperwork—it’s about making sure your protection system reacts in milliseconds when it matters most. It’s about keeping the insulation healthy, ensuring contacts stay clean, allowing mechanical parts to move freely, and making sure protection systems respond instantly during faults. Skipping these essentials can leave your entire electrical network exposed when you need it most.

By the way… want to know what happened at a plant that skipped relay testing? Let’s just say it led to more than just equipment damage.

The full story (and how to avoid it) is inside the free guide at the end of this blog. (Hint: Jump to Page 3)

How Often Should You Test Switchgear?

There’s no one-size-fits-all answer—because every site is different. Factors like load criticality, environmental conditions, and manufacturer recommendations all play a role.

But here’s a simple rule of thumb (that won’t put you to sleep):

- Visual checks and thermal scans? Every 6 months.

- Electrical and functional tests? Annually.

- Full shutdown maintenance with deep diagnostics? Every 3 to 5 years.

In short… don’t wait for your switchgear to give you a loud, smoky reminder!

Breaker Testing – Your First Line of Defense

Breakers spend most of their life waiting for that one critical moment… the moment a fault happens. But when that moment comes, they must react instantly.

At Petrozone, we start with a detailed visual check—looking for dust, burn marks, or worn parts. Then we test the insulation, measure contact resistance, check timing accuracy, and perform high-voltage withstand tests. After that, it’s all about cleaning, lubricating, and making sure the breaker feels like new again.

(By the way… if you want a full maintenance checklist for breakers, it’s inside the free guide at the end of this blog.)

Protection Relay Testing – The Brain Behind the Trip

Even a perfect breaker can’t trip if the relay doesn’t tell it to.

That’s why we run through visual checks, communication port tests, simulate protection functions like overcurrent and earth fault, and verify every input and output. We also check the trip circuit and make sure event recording is working fine.

There’s a famous relay failure story from one of our projects… (Hint: Page 3 of the free guide has all the details—you’ll want to read it before your next shutdown!)

Busbar Testing – Keeping the Current Flowing

Busbars handle the heavy lifting inside your switchgear. If joints loosen or insulation weakens, things can go south fast.

We check insulation resistance, measure contact resistance across joints, and visually inspect for discoloration or hotspots.

One loose joint… one hidden fault… that’s all it takes.

(You’ll find more on busbar care in the free maintenance checklist.)

CT, VT, and Meter Testing – Your Eyes and Ears

CTs and VTs feed data to your relays and meters. If they’re giving wrong signals, your protection system makes wrong decisions.

Our testing covers CT ratio, polarity, insulation, and excitation. We test VT ratio and insulation too, plus check meter calibration and wiring continuity.

(Want a simple CT/VT testing reference? It’s inside the guide!)

Panel-Wide Visual and Mechanical Checks – The Small Stuff Matters

We wrap up with mechanical and safety checks—testing door interlocks, earth continuity, terminal tightness, and doing a full panel clean-up.

Because honestly… even one loose screw can turn into a big headache.

Download Your Free Switchgear Maintenance Checklist and Self-Assessment Guide

To make your job easier, we’ve created a practical, field-tested PDF guide—built by engineers, for engineers.

Inside the guide, you’ll find:

✔️ A visual inspection checklist to cover all critical areas

✔️ Recommended test intervals for each type of maintenance activity

✔️ A quick-reference list of red flags you should never ignore

✔️ And a self-assessment section, where your team can rate the current health of your switchgear and track overdue maintenance

Whether you’re preparing for your next shutdown or just want to check how well your system is holding up… this guide will help you take action before small issues turn into big problems.

Final Thoughts: Let’s Keep Your Power Flowing Safely

Switchgear maintenance isn’t just another item on your task list—it’s an essential step toward preventing failures, protecting your assets, and ensuring uninterrupted operations.

At Petrozone International, we combine field experience, technical expertise, and a deep understanding of the conditions industries face across Saudi Arabia.

Whether you’re planning a shutdown, preparing for your next annual maintenance, or facing an urgent issue… we’re ready to help.

✅ Need a site visit?

✅ Want a custom maintenance plan?

✅ Or simply want to talk to an expert?

👉 Contact Petrozone today and let’s make sure your switchgear stays ready when it matters most.

Related Links & Further Reading

Looking to explore more about our services and expertise? Check out the following pages:

🔗 Cable Termination Services – Discover how we handle MV cable terminations with precision and reliability.

🔗 Erection & Installation – Learn more about our process for safely installing electrical equipment and infrastructure.

🔗 Testing & Commissioning – Explore our comprehensive testing protocols that ensure safe energization.

🔗 Contact Us – Got a similar project? Reach out to us today and let’s get it done, the Petrozone way.